Description:

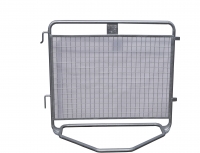

STG 35 Forklift pallet for all conventional steel gratesRegistered design number 20 2010 010 099.2

Almost all barrier grates from all manufacturers can be transported on this stackable pallet.

What's unique about this pallet is that the steel barrier grates can be carried on the lowest horizontal side rails and transported vertically.

This ensures that the upper side rails won't be scratched by scraping against other steel barrier grates.

The product also stays clean as the feet are not tilted upwards.

With this pallet, the feet are vertical, next to the side rails of the palette.

The first pallet is secured with a hinged bracket to ensure that the steel barrier grates don't fall over on the pallet.

Between 30-50 steel barrier grates can fit on a STG 35 universal pallet, depending on the manufacturer and the size of the grate.

Capacity of the STG 35 for our products:

- C 2 Light: 38 units (feet facing downwards)

- C 2 Heavy: 34 units (feet facing downwards)

- C 3 Heavy Police Grate: 16 units

If they are stacked crosswise you can fit twice as many!

Another special feature of the STG 35 Universal Pallet is that it can be stacked, saving considerable storage space. Of course, two STG 35 Universal Pallets can also be transported on top of each other on a lorry, but please keep in mind that the load must be secured.

The feet of the steel barrier grate in the upper STG 35 Universal Pallet don't touch the handrail of the steel barrier grate stored in the STG 35 Universal Pallet stored below.

The feet can be repositioned using the self-securing locking pins, depending on the type of steel barrier grate.

When the STG 35 Universal Pallet is empty, the side rails can be inserted into the feet for transport purposes.

When transporting it empty, the STG 35 Universal Pallet has a height of 80 mm.

With the STG 35 Universal Pallet, you can pick up stacked steel grate pallets, e.g. with an elongated pallet fork.

For this purpose it is required that you bolt the fork mount supports as high as possible and hang the front supports from the hooks intended for this purpose on the rear supports.

Next the finished stack can be loaded and the fork can be lifted at the front so that the fork tilts slightly backwards.

The front supports can now be easily inserted and bolted so that the feet of the steel barrier grate doesn't touch the floor. Tilt the pallet slightly forward so that the rear supports are free and can be pushed back deeper depending on the dimensions of the feet.

Inquiry

Inquiry Favorites

Favorites